Critical project execution for the refining and petrochemical industries

Diamond’s dedicated refractory specialists have an enormous reach. From alloy welders and nozzlemen to safety professionals and skilled laborers, Diamond’s team can handle virtually any situation.

CAPABILITIES

We are a Texas-based refractory specialist that has been providing refractory turnaround services to the refining and process industries since 1999. Read about our expanding products and markets.

SAFETY

More than just a priority, safety is one of Diamond Refractory’s core values. As such, we’ve created a culture in which safety thrives.

Meet the Team

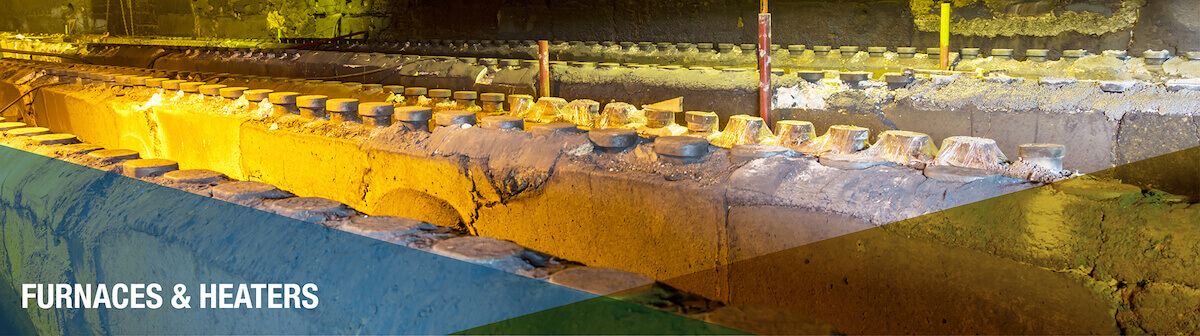

Chase Drake, President & Engineering Manager, oversees Diamond Refractory’s full range of services from turnarounds to furnaces and heaters, to acid proofing.

Chase Drake, President & Engineering Manager, oversees Diamond Refractory’s full range of services from turnarounds to furnaces and heaters, to acid proofing.

120+ FCCU TURNAROUNDS AND COUNTING

We service refinery and petrochemical clients within the U.S. and select international locations.

COMPREHENSIVE REFRACTORY SERVICES

Diamond can expedite and reduce response times on turnaround projects by using our own trucks to deliver equipment and material. We offer clients comprehensive, complete, and turnkey turnaround services.

API 936 CERTIFIED SUPERVISORS

Each of Diamond’s supervisors are API (American Petroleum Institute) 936 Refractory Quality Control Personnel, helping to ensure that each supervisor working on your project has been prequalified and meets the highest standard the industry offers.